Company Introduction

Established in 2013 and headquartered in Singapore, Pumport Engineering Pte Ltd is a trusted provider of comprehensive solutions for industrial fluid and gas handling systems. Specializing in the supply, maintenance, and support of critical equipment, we cater to diverse industries with a focus on quality, reliability, and customer-centric service.

Why Choose Us

WE ARE PASSIONATE

We have a proven record of accomplishment and are a reputable company in Singapore. We ensure that all projects are done with utmost professionalism using quality materials while offering clients the support and accessibility.

HONEST AND DEPENDABLE

For us, honesty is the only policy and we strive to complete all projects with integrity, not just with our clients, but also our suppliers and contractors. With thousands of successful projects under our belt, we are one of the most trusted companies in Singapore.

WE ARE ALWAYS IMPROVING

We commit ourselves to complete all projects within the timeline set with our clients. We use the best of technology and tools to ensure that all jobs are done quickly but also giving attention to details and ensuring everything is done correctly.

Who We Are?

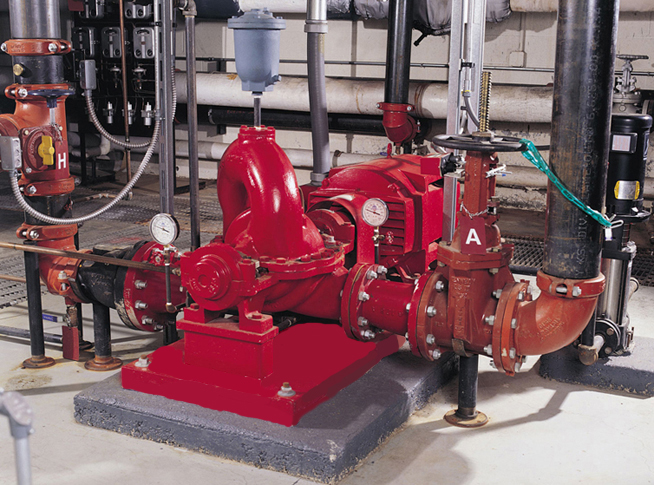

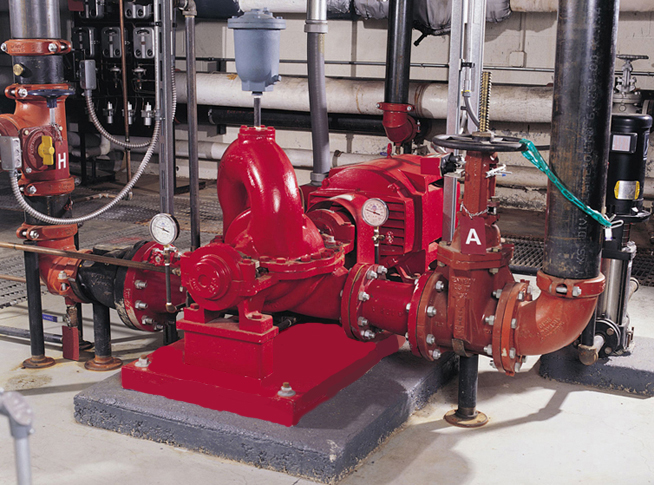

Pumport Engineering Pte Ltd was established to server the pump industry in both water treatment and oil and gas sector. Supplying various type of pump, range from UL listed Fire water Pump, API 610 Horizontal Centrifugal Pump, Vertical Pump, Submersible Pump, Self Priming Pump, Later in the business milestone, Pumport Engineering Pte Ltd extend their business into Piping and fitting business. We design and fabricated all our sk which comply to our client’s standards. With our experience in this industry, we provide competitive and reliable solutions to our clients via innovative products, service ...