Chemical Injection Skid Introduction

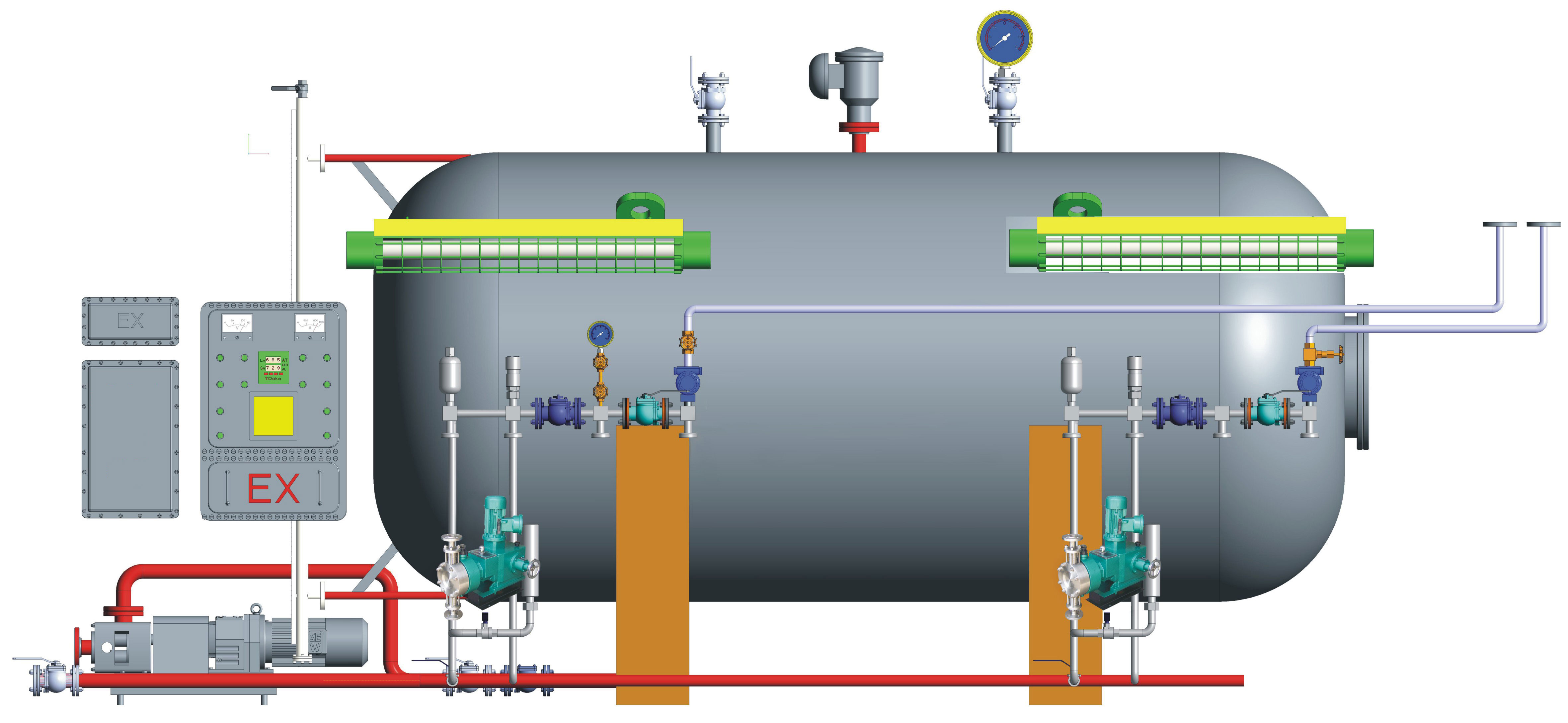

A chemical injection skid is a device or equipment used along with pumping systems to inject chemical into the stream at precise flow rates and preset pressures. The equipment consists of a pump, a tank strainer, a calibration gauge, a pulsation dampener, pressure gauges, and other flow rates indicators. The material used for constructing a chemical injection skid depends on the chemical that is being used.

Chemical injection skids are commonly used in water treatment plants to offer critical reagents for standard operation conditions. In some cases, several skids could be installed to include multiple units that deliver reagents at various points in the treatment system. The systems are usually designed to deliver a constant stream of concentrated reagents at very precise volumes in order to ensure bulk concentrations in the main process line are maintained.

How it works

The pumping rates, dilution water flow rates and the concentration of chemicals is monitored using on-line instrumentation. The control of these parameters is normally through valves that receive signals from the water treatment systems programmable logic controller.

All chemical dosing capabilities in a chemical injection skid can be achieved through an integrated sizing that is based on the total flow rates of the system design. Additionally, skids can be physically constructed to suit a wide variety of footprints and environments based on certain application requirements.

Common Materials

A chemical injection skid is normally used alongside positive displacement pumps and centrifugal pumps. They are usually constructed from corrosion resistant steel, lined steel, and PVC piping. For more robust and extreme applications, they are constructed from heavy duty structural steel that may be blasted, primed, and finished with a coating of two-part epoxy. Others may be made from carbon steel and more exotic alloys.

Most chemical injection skids are often sophisticated and come with remote controls and intrinsic alarms for monitoring high and low pressure, temperature pressure drop feed, and conductivity. Some systems could also include PLC systems for local and remote control and could include connections to a control center.

Applications

The most common application for the chemical injection skid is in drinking water treatment in municipal water supply facilities. They are also used in waste water treatment facilities and also in various industrial and commercial water treatment applications. Chemicals are often injected in water to control pH, control mineral fouling in mining applications, control bio fouling in some industries, and to increase solubility limits.

- Flocculant Injection Skid

- Coagulant Injection Skid

- Caustic Injection Skid

- Acid Injection Skid

- Antiscalant Injection Skid

- PAC Injection Skid

- Chlorine Scavenger Injection Skid

- Biocide Injection Skid

- Antimicrobial Agent Injection Skid

- Oxygen Scavenger Injection Skid

- MEG/Methanol Injection Skid